Aluminium profile milling and cutting

Aluminium profile milling and cutting - KABAN - ZC 2010

- It performs the milling and cutting operations of the profiles.

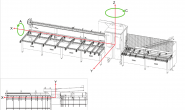

- There is a SERVO motor-controlled processing unit that allows all desired operations on the part.

- Stress relieving method has been applied in casting and aluminum parts to ensure continuous precision.

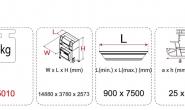

- Profile dimensions of maximum (a x h) 150 x 190, minimum (a x h) 25 x 10.

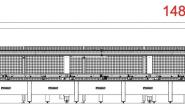

- Waste can be automatically optimized and evaluated within the cut lists sent.

- There is a working algorithm in accordance with the principle of minimum waste and maximum production.

- It has profile moving and positioning, automatic profile recognition feature.

- Tool cooling system with oil-air mixture spraying speed adjustment, liquid level sensor. It has a periodic maintenance reminder function.

- Parameter settings can be made easily.

- ROBUST mechanical system suitable for high speed.

- It has an automatic lubrication system.

- Production capacity can be planned.

- 19 '' Kiosk, USB, Com port input, Service support with remote connection.

The machines illustrated on this website are under continuous development, we reserve the right to change dimensions and designs. The illustrations may differ from the actual version of the machines and/or may include options at extra cost.