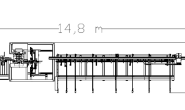

Cutting and processing line for profiles

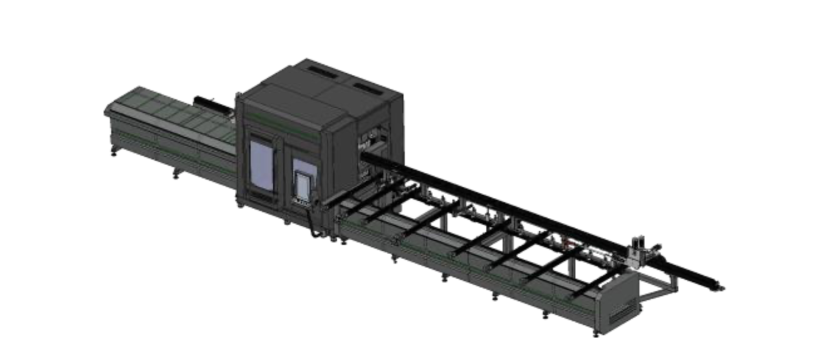

Cutting and processing line for profiles - Mepal - OLYMPUS

The cutting and processing line for profiles OLYMPUS consists of 4 main parts:

1.Loading side (3 controlled axis):

-automatic loading table with gripper to hold and feed the profile, useful bar length 6500 mm; maximum carriage speed 170 m/min.

-the belt on the loading table allows to load a maximum number of 9 bars.

-the gripper with 2 controlled axis allows the quick positioning depending from the loaded profile.

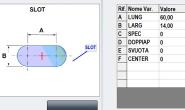

2.Milling side (3 controlled axis):

-milling units with 9 ELECTROSPINDLES at 24000 RPM and 1 ELECTROSPINDLE with 3 drills unit at 1400 RPM.

The positions of the spindles are adjustable to adapt to any type of machining and profile and the high rotation speed of the tools allows maximum effectiveness in milling.

-3 controlled axis allow the milling unit to move in X Y Z and therefore guarantee the maximum precision and speed of execution of the processes.

-X axis with a 600 mm stroke allows the cutting while milling operation to reduce at the minimum the working time.

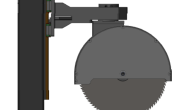

3.Cutting side (2 controlled axis):

-single-head descending miter saw with Ø550 mm blade for cuts at any angle between 45° and 135°. The downward cut allows easy unloading of the chips and swarf.

-cutting angle positioning between 45° and 135° by means of a brushless motor and high precision gearbox with 0 play “robotic grade”.

-the cutting and milling area are protected by a cabin ensuring also a noise reduction.

4.Unloading side (1 controlled axis):

-the unloading carriage allows to take the piece just cut and take it outside the cutting area.

-the unloading table receives the pieces that are pushed away by the saw and, through an ejector, then makes them available to the operator.

-the unloading table with scratch-resistant strips allows to host up to 8 pieces before the operator collects them.

Maximum bar that can be loaded: 6500 mm

Maximum bar that can be unloaded: 3000 mm, different lengths on request

Minimum cut at 90°: 250 mm

All movements on high precision linear guides, ballscrews or helical rack