Double Head Welding Machine

Double Head Welding Machine - Mepal - Ghibli S2

The GHIBLI S2 PVC profile welder is a two-head welder capable of welding profiles at 90° and at variable angles with both heads.

The machine is equipped with quick-change fixture changing system, seam limiting knives, and the ability to weld a maximum height of 200 mm.

The temperature can be adjusted between 0° and 350°C via the digital control on the machine.

The mobile head and all other movements are on linear guides with recirculating ball bearings, ensuring no play and precision in positioning.

The control panels on both heads are equipped with the following controls: profile clamping, automatic cycle start, two-hand controls; emergency buttons; manual reset emergency control; pneumatic button on the mobile head for locking it in position.

Quick change of Teflon.

INCLUDED ACCESSORIES :

• No.2 front profile support arms

GHIBLI S2

By purchasing our GHIBLI S2 and special welding blocks, it is possible to integrate the GHIBLI S2 into our V seamless welding system to achieve seamless angles on the outer parts of the frame (only on the top or on the bottom). Our CNC contouring center EDGE is necessary.

GHIBLI S2 V

The special version GHIBLI S2 V does not require special welding blocks; however, with high quality standard welding blocks, it is capable of performing seamless V or flat welding after contouring the profiles on our CNC contouring center EDGE.

• Fixed welding unit on the left

• Mobile welding unit on the right

• Maximum profile height: 200 mm

• Maximum length: 3000 mm

• Front profile support arms that assist the operator in welding two angles simultaneously

• Welding of angles different from 90° with both heads

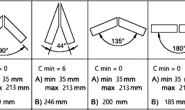

• Welding of out-of-square angles and quick, precise resetting to 45° with mechanical stops (from 30° to 180°)

• Welding of angles with a 45° or 90° finish in a single cycle, selectable from the display

• Automatic retraction of the mobile head at the end of the work cycle

• Temperature of the welding plates, fusion times, and welding times adjustable via graphical PLC

• Pressure sensor

• Automatic control of fusion times adjustable from the display

• Automatic control of welding times adjustable from the display

• Coil heating of the welding plates ensures uniform temperature across the entire surface

• Milled fusion plates with the option to replace only the coil and not the entire aluminum plate

• Low-pressure gravity descent of the clamps

POWER TECHNICAL DATA:

• Voltage 380 V 3PH+PE (220 V 3PH+PE on request)

• Requested power 5 kW

• Working pressure 7-8 bar